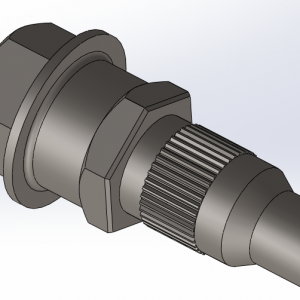

Our engineers have extensive experience and expertise in developing your most difficult component problems into cold headed solutions. State of the art methods such as 2D, CAD, 3D solid modeling, and finite element analysis are used to produce a vast array of parts. Technical “know how”, coupled with advanced cold heading, shaving, drilling, roll forming, threading, and grooving processes uniquely qualify Grandeur Fasteners as a leader in engineered metal components.

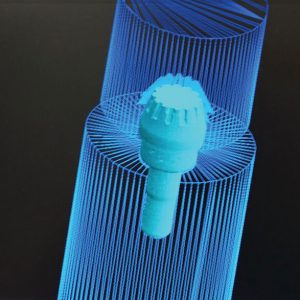

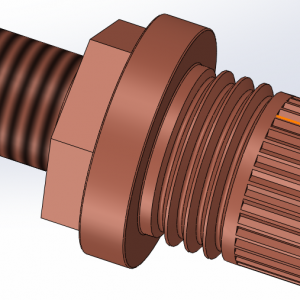

Advanced computing and design software is utilized by our engineering team to evaluate your components for suitability to the cold heading process. We can also provide 2D and 3D design solutions backed by the use of stress analysis software and mathematical models.

Contact Grandeur Fasteners today and let our engineering team evaluate your current products for cold heading suitability, or assist in the design of new products from the earliest stages of development.

- In-house design and fabrication facility for all required tooling

- Computer software analysis

- Engineering tool solid works: 3D engineering

- 3D print capabilities

Management Control Tooling

Our customer and part specific tooling program reduces lead times by organizing and stocking tool sets. Having multiple backup tool sets allow us to quickly replace or make changes to our header machines when problems arise. Broken tooling can take up to several weeks for replacement, but our tooling inventory program ensures we get it done on time.